Inventory management plays a vital role in businesses. It enhances preparedness to respond to the market’s demand forces. This means that everything from stock records to storage costs falls under inventory management.

Sounds like a big deal, right? Manually dealing with such a tedious and meticulous task is a big deal as well. Which is why businesses are shifting to AI to make things easier. AI in inventory management utilizes technologies, like ML, computer vision, IoT devices, and many more. These help businesses multiply their productivity and reduce the costs of maintaining optimal inventory levels.

This blog gives you a deeper understanding of how AI takes the struggle out of inventory management and makes the tedious processes easy-peasy.

Key Takeaways:

- AI in inventory management replaces manual management procedures with automation.

- It utilizes ML, computer vision, and IoT that optimize inventory workflows

- AI in inventory management forecasts demand, tracks activities, and automates tasks.

- It boosts efficiency, saves costs, makes decisions faster, and reduces downtimes in warehouses.

- Future trends indicate the rise of agentic AI, hyper-personalization, autonomity, and sustainability.

- Core implementation challenges include data concerns, high investment, and integration limitations.

What is the Role of AI in Inventory Management

When we talk about the role of AI in inventory management, the first thing that clicks is the value it adds to businesses. AI utilizes ML, computer vision, automation, IoT devices, and data analytics to manage inventory efficiently.

It combines these technologies to deliver an AI system that tracks stock levels, ensuring the availability of the right goods in the correct quantity and at the optimal time. The role of AI in inventory management is much more than just maintaining inventory levels.

AI understands inventory management at a deeper level. This enables it to forecast future demands and needs. In simple words, the role of AI in inventory management is to manage stock levels in a way that they meet the current as well as future market demand.

Common Challenges in Inventory Management

In traditional settings, businesses face several inventory management challenges. These challenges impact the effectiveness and efficiency of inventory management. Let’s take a look at some of these challenges:

Lack of Precise Inventory Visibility

In the traditional setting, the record-keeping is done manually. This often leads to inaccurate or unupdated records that do not provide precise inventory information. Without knowing the actual availability of goods, businesses often end up either overstocking or understocking.

Inventory Balance Issues

Establishing a balance in the inventory levels becomes challenging when done manually. Businesses often end up overstocking, which later results in products being damaged. Another part of this challenge is understocking, which often leads to businesses failing to keep up with the market demands for the goods.

Ineffective Demand Prediction

Businesses that depend on manually handled inventory management systems rely on experience to predict demands. Since market demands are not fixed and fluctuate frequently, these predictions often fail in providing an accurate forecast.

Time-Consuming Processes

Traditional inventory management systems do every procedure manually. All the records, paperwork, stock levels, reports, etc, are made manually. Naturally, all of this takes a lot of time and hence impacts overall efficiency.

Scalability Challenges

When a business grows, the inventory levels also grow with it. Being handled manually, the traditional inventory management systems fail to keep up with the business. Scaling is challenging in a traditional setting because the stock levels requirements increase, making it hard to manage manually.

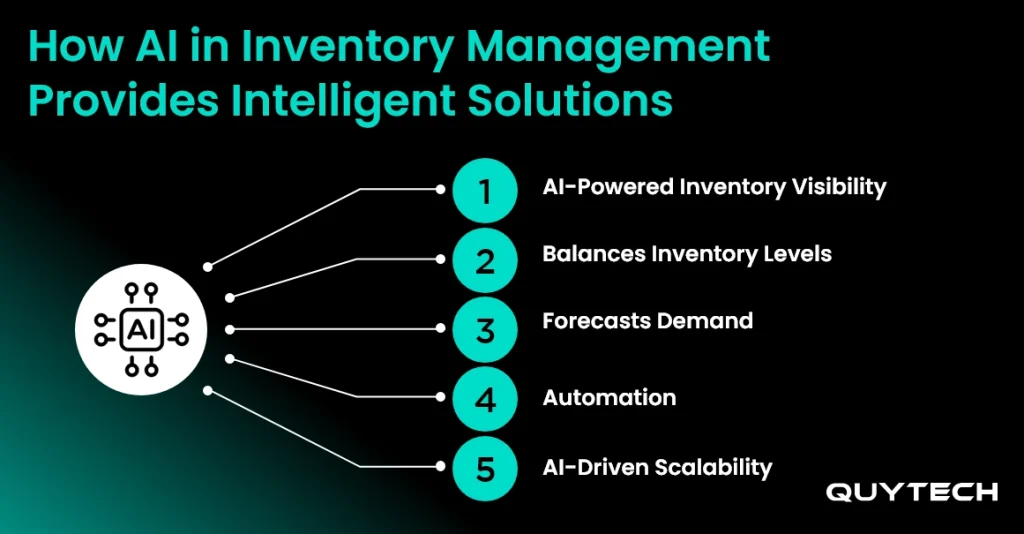

How AI in Inventory Management Provides Intelligent Solutions

Now that you’re aware of the common challenges of inventory management, let’s explore how AI in inventory management provides intelligent solutions:

AI-Powered Inventory Visibility

AI provides a real-time view of the inventory levels. It does so by gathering the data through IoT devices, analyzing it, and interpreting it for the personnel handling the dashboards. Along with this, it also provides data-based insights for enhancing inventory management strategies.

Balances Inventory Levels

AI solves the challenges of balancing inventory levels with its algorithms. AI algorithms analyze the demand, supply, and also calculate the time for replenishment. This helps in ensuring that there is no waste of resources and they are utilized efficiently.

Forecasts Demand

Demand forecasting is a tough task and should not be done based on intuition. AI brings in technologies like machine learning and predictive analytics. These technologies analyze past data, the user behaviour, along with economic and seasonal fluctuations.

Automation

AI makes the tedious and time-consuming tasks easy. It does so by utilizing robotic process automation and workflow management algorithms. This reduces not just the time but also the cost spent on hiring people to do these repetitive tasks.

AI-Driven Scalability

Scalability becomes easy with AI, as the business does not have to hire more people to handle increased tasks. AI utilizes machine learning that can handle large workloads and data sets as well. This means that businesses can earn more without spending more on hiring a workforce.

You Might Also Like: Role of Artificial Intelligence in Legal Firms: Enhancing Efficiency and Accuracy

Key Use Cases of AI in Inventory Management

Now that we know how AI in inventory management helps businesses, it’s time to explore the use cases. Here are some of them:

| Use Case | Description |

| Accurate Forecasting | AI analyzes all the current and past data regarding sales, fluctuations, and seasonal variations to predict demand and manage inventory accordingly. |

| Inventory Tracking | AI keeps a real-time track of stock movement in the warehouse, ensuring that everything is managed and monitored. |

| Automated Reordering | AI is autonomous to a certain extent, which makes it capable of purchasing goods when it reaches a minimum level. |

| Warehouse Management | AI systematically manages the warehouse with the help of automation and computer vision. It manages product placements, assists with supply chain coordination, and creates storage layouts. |

| Supply Chain Risk Management | AI monitors supplier behavior, time taken for replenishment, and events that can lead to delays. This prepares businesses to tackle unexpected situations. |

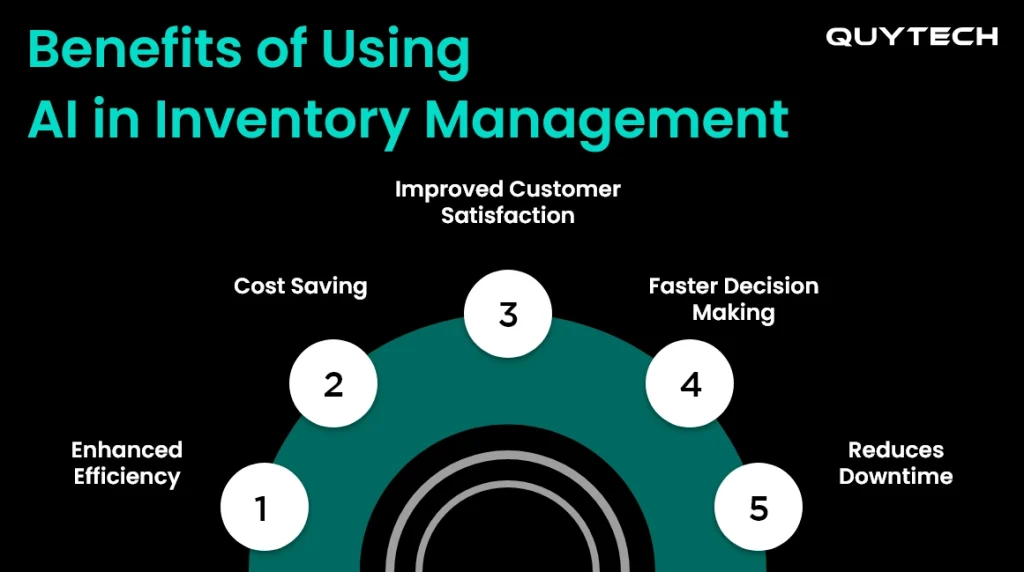

Benefits of Using AI in Inventory Management

AI in inventory management brings numerous advantages that help businesses bloom

Let’s take a look at some of the benefits:

Enhanced Efficiency

AI in inventory management automates the tedious tasks that take hours and completes them within minutes. This speeds up the process of task completion. It enhances the overall efficiency of the warehouse.

Cost Saving

AI saves a lot of costs that businesses spend on managing the inventory. It saves the cost of hiring a human workforce for repetitive tasks. Along wth this, it also saves the resources that get wasted in case of overstocking.

Improved Customer Satisfaction

With accurate demand and resource forecasting, AI in inventory management contributes to improving customer satisfaction as well. It ensures the stocks are available when demanded, which helps in meeting the expectations of customers.

Faster Decision Making

AI tools don’t just crunch numbers; they track data as it happens. Instead of waiting hours for reports, you can get instant alerts and practical suggestions right when you need them. These alerts help businesses make the right decisions on time and minimize the time spent on decision-making.

Reduces Downtime

AI in inventory management uses predictive analytics to analyze real-time data. This predicts maintenance needs. It enhances the business’s preparedness against sudden downtimes. Predictive analytics assist businesses in taking the required maintenance actions.

Read More: AI in Insurance Claim Processing: Cut the Costs, Fraud, and Delays

Real-World Examples of AI in Inventory Management

Here are some of the major real-world examples of AI in inventory management:

Amazon

- Amazon utilizes artificial intelligence and machine learning models to predict future demands for products. It maintains stock levels based on that information.

- It also makes use of automated ordering technology to replenish inventory stock.

Walmart

- Walmart makes use of autonomous robots that scan the store and collect data on items that need restocking.

- This scanning is supported by an AI-based automated ordering system.

Nike

- Nike manages its global inventories with the help of AI-powered inventory management systems.

- It also forecasts future demand for its products using AI-powered tools.

Target

- Target makes use of AI tools to predict product demands by analyzing data.

- It utilizes data-backed insights to make informed inventory management decisions as well.

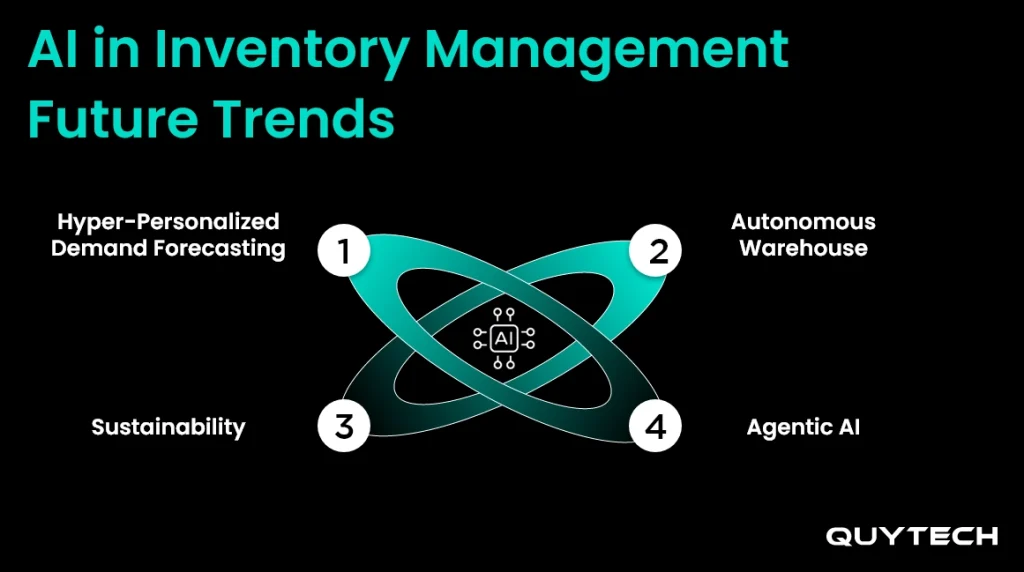

AI in Inventory Management: Future Trends

Implementing AI means tapping into a market that has immense future potential. So let’s explore some upcoming trends of AI in inventory management:

Hyper-Personalized Demand Forecasting

AI will not be confined to forecasting demand for a population. Instead, it is expected that AI will move to a hyper-personalized demand forecasting model where it will focus on the demands at the individual level.

Autonomous Warehouse

The AI-powered warehouses in the current scenario scan and order stock replenishments. In the future, AI will completely automate the warehouse operations. It will handle everything from stock packing to sorting.

Sustainability

The future AI in inventory management will incline towards a sustainable management method. AI will carry out the activities in a way that contributes to sustainability. Environment-friendly warehouse management will be practiced.

Agentic AI

Agentic AI will be integrated into the inventory management systems. All the tasks will be carried out by agents. They will plan the actions, execute, and improve their management skills from every interaction.

Similar Read: AI in Customer Service 101: Use Cases, Benefits, Challenges, Implementation Process, and More

Considerations for Implementing AI in Inventory Management

‘Every coin has two sides.’ This perfectly explains that there is more than just sparkles when it comes to utilizing AI. Here’s a breakdown of the challenges of using AI in inventory management:

Inconsistent Data

Many businesses that depend on manual inventory management systems do not have consistent data. The challenge arises when a business shifts from traditional to AI systems, but its data remains scattered across departments. This impacts the process of AI integration.

High Initial Investment

The initial investment that businesses require to implement AI in their inventory management system is quite high. This often makes them reluctant to adopt the technology.

Businesses should understand that even though the initial investment is high, the return makes it worth it.

Data Security Concerns

AI in inventory management utilizes data that is often sensitive and crucial. Handling such data becomes a prominent responsibility as data breaches and cyberattacks can cause significant loss to a business. However, this can be prevented by complying with data security regulations.

Integration Challenges

Many times, businesses are not able to easily integrate AI into their inventory management system. This situation arises when the existing systems are not compatible with sophisticated AI software.

But like any other issue, this also has a solution. Businesses can consider getting a custom-made solution for easy integration and effective results.

Integrate AI in Inventory Management with Quytech

Quytech helps businesses in integrating AI solutions into their inventory management systems effectively. With over 14 years of industry experience, we excel at developing AI solutions tailored for your business.

Our team of dedicated developers closely communicates to successfully integrate AI solutions into your existing management systems. Not just integration, we also build customized AI-powered inventory management solutions that grow with your business seamlessly.

Conclusion

In a world so competitive, no business wants to fall behind. Naturally, they are turning to advanced AI technologies to stay ahead. This reflects how AI in inventory management is becoming a necessity.

AI improves efficiency by saving costs and enhancing customer satisfaction. It facilitates faster decision-making and reduces downtime, which helps businesses perform to their potential. Hence, implementing AI in inventory management is not about staying attentive but about being proactive.

FAQs

Yes, AI can help small and medium businesses with inventory management. It helps in effectively managing stock levels and saves costs as well.

No, AI should not be seen as a technology that replaces human roles. Instead, it assists humans to perform better by handling the repetitive portion of their tasks.

Yes, AI can integrate with existing inventory management systems. This helps businesses in implementing technology without a high investment.

Yes, AI analyzes all the data that can contribute to and impact demand levels, which includes seasonal and unexpected demands as well. So AI is capable of handling these demands.

Absolutely, AI-powered inventory management tools utilize machine learning algorithms that are capable of handling large amounts of data.