In many manufacturing and similar organizations, poor product quality (including defects and rework) can take away up to 20% of the overall sales revenue and up to 40% of the total operating cost. Even successful manufacturing companies may lose up to 15% of their overall operations budget as COPQ (cost of poor quality).

This raises an alarm for manufacturing companies to switch from conventional quality control to AI-powered quality control. Traditional ways involve manual inspections and random sampling, whereas AI quality control in manufacturing offers accurate defect detection, equipment issues prediction, and resource optimization, which leaves no room for errors, delays, and wastage.

Wait, are these the only use cases of implementing AI in quality control for manufacturing? Definitely not! This well-researched blog thoroughly explains how AI enhances quality control in manufacturing, its benefits, challenges, implementation process, and a lot more.

What are you waiting for? Let’s quickly begin!

AI in Quality Control: What does it Mean

First things first! Artificial intelligence in quality control in the manufacturing industry means using AI and its subsets, including computer vision, machine learning, and real-time data analysis, to monitor, analyze, and boost product quality.

How?

We are all aware of AI’s data handling and processing capabilities. In the manufacturing sector as well, AI makes the most of real-time manufacturing data to identify deviations at an early stage or even proactively. When defects are detected earlier, quality control managers or supervisors can vouch for the quality of the product.

AI quality control in manufacturing means having an eagle eye during the product manufacturing to avoid errors and improve efficiency. Let’s understand how AI in manufacturing quality control works:

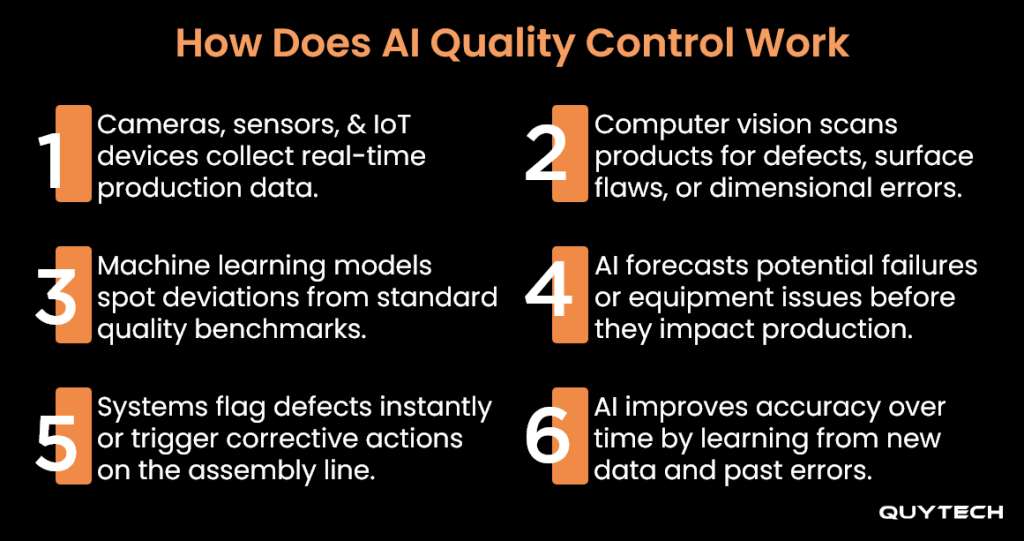

How does AI Quality Control Work

- Cameras, sensors, and IoT devices collect real-time production data.

- Computer vision scans products for defects, surface flaws, or dimensional errors.

- Machine learning models spot deviations from standard quality benchmarks.

- AI forecasts potential failures or equipment issues before they impact production.

- Systems flag defects instantly or trigger corrective actions on the assembly line.

- AI improves accuracy over time by learning from new data and past errors.

Traditional Manufacturing Quality Control Vs. AI-Powered Manufacturing Quality Control

As aforementioned, conventional ways of quality control involve manual inspection, which might not be highly precise. This may not only lead to poor product quality but also increase the cost of manufacturing a product due to rework, returns, or production delays. Let’s understand the difference between traditional quality control in manufacturing and AI-driven quality control in manufacturing:

| Aspect | Traditional Quality Control | AI-Powered Quality Control |

| Accuracy | Completely relies on human judgment, prone to errors and oversight | Leverages AI, ML, CV, and other technologies to detect even micro-defects with high precision |

| Speed | Time-consuming as manual inspections slow down production | Offer real-time defect detection without slowing workflows |

| Consistency | Results vary depending on the inspector’s skill and focus | Delivers uniform and reliable quality checks every time |

| Cost | High labor costs, rework, and wastage | Cuts costs through automation and early defect detection |

| Scalability | Difficult to scale without large manpower | Easily scales across multiple production lines |

| Defect Detection | Limited to visible or sampled issues | Identifies subtle flaws, surface anomalies, and predictive risks |

| Approach | Reactive, it detects problems after they occur | Proactive; it predicts, prevents, and improves continuously |

| Data Utilization | Involves minimal use of production data | Leverages big data and analytics for actionable insights |

How does AI Enhance Quality Control in Manufacturing

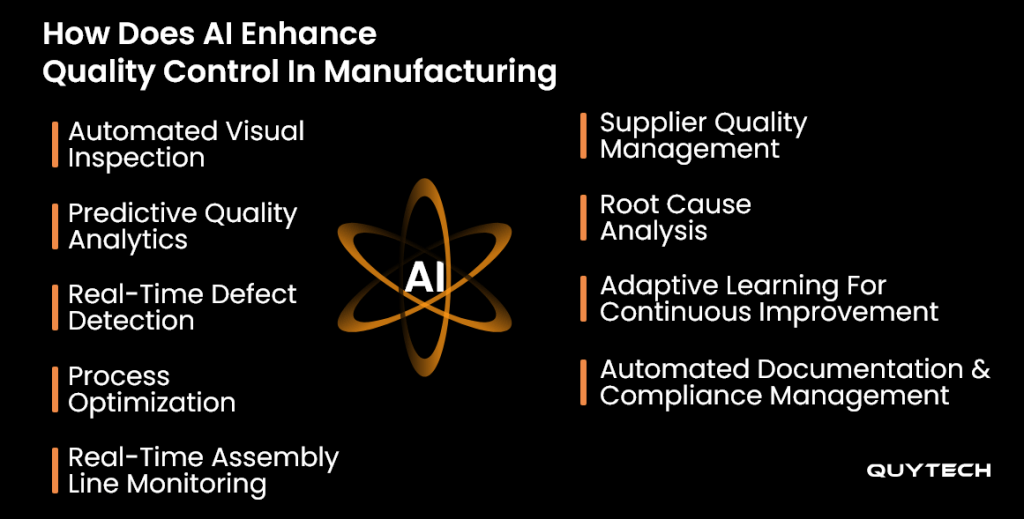

Artificial intelligence transforms quality control in manufacturing by automating inspection of the assembly line, offering predictive insights about the occurrence of potential issues, detecting defects in real-time, and in so many other ways. Let’s take a look at the most impactful use cases of AI quality control in manufacturing:

#1 Automated Visual Inspection

The first use case of AI in quality control in the manufacturing industry is automated visual inspection. AI, along with computer vision, scans and analyzes products being manufactured on multiple assembly lines to identify defects like scratches, dents, misalignments, and incorrect dimensions. Using AI for automated visual inspection in manufacturing guarantees the highest degree of precision and consistency in quality control.

#2 Predictive Quality Analytics

Using AI for predictive quality analytics in manufacturing empowers manufacturers to adopt a proactive approach towards defect prevention. The technology rigorously monitors production equipment and machinery for any wear and tear and quality issues, which may lead to the production of faulty products.

#3 Real-Time Defect Detection

Implementing AI for defect detection in manufacturing facilitates instant detection of anomalies or defects. AI continuously analyzes smart data collected by sensors and IoT devices attached to the production or manufacturing machinery or equipment. This data could be about the machine’s/equipment’s temperature, vibration irregularities, or defects in the material being used for manufacturing. Based on the analysis, it alerts the operator in real-time to prevent the manufacturing of defective or poor-quality products.

#4 Process Optimization

Artificial intelligence in manufacturing quality control can be used to identify inefficiencies in processes or workflows that are responsible for ensuring product quality. AI can be used to ensure or optimize each machine’s settings based on the product that needs to be manufactured on it. This could be maintaining the right production speed, accuracy, and adhering to defined standards.

#5 Real-time Assembly Line Monitoring

Manufacturing quality control using AI empowers manufacturing companies to ensure round-the-clock and precise monitoring of the assembly lines. AI ensures that every component of the assembly line is placed correctly and functioning properly to avoid the production of faulty products and minimize the risk of expensive rework or re-production.

#6 Supplier Quality Management

Artificial intelligence for quality control in manufacturing can even help with supplier quality management. The technology leverages historical data and inspection results to ensure the quality of the raw materials that the company procures from different suppliers. Based on the analysis, it can provide managers with insights into the reliability of the supplier and the quality of the raw materials.

#7 Root Cause Analysis

AI can be used for root cause analysis of the issues or defects that occur during the manufacturing of a product. While this is a reactive approach, knowing the root cause of the defect can help supervisors to prevent its occurrence in the future and shorten the problem-solving lifecycle. AI, along with advanced analytics, tracks the cause to find whether the issue occurred due to faulty equipment, errors in the process, or raw material used.

#8 Adaptive Learning for Continuous Improvement

Manufacturing quality control using AI requires minimal human intervention, even when the new data evolves. AI-powered quality control systems can automatically analyze new data, inspection outcomes, and previous errors to re-train the models for accuracy in defect detection, providing proactive insights and ensuring flawless production.

#9 Automated Documentation and Compliance Management

AI-powered quality control solutions for the manufacturing industry automate document and compliance management. The technology eliminates the dependency on human resources to perform inspection and documentation-related tasks. This reduces paperwork, accelerates time-to-market, and ensures adherence to defined quality standards.

What are the Benefits of AI-driven Quality Control in Manufacturing

Adopting intelligent automation in manufacturing quality control brings the highest degree of accuracy and speed in defect detection. It also ensures cost reductions by minimizing the chances of rework or manufacturing the product from scratch due to a fault or poor quality. Let’s explore the benefits of AI quality control in detail:

#1 Accuracy in Defect Detection

AI-powered quality control systems can efficiently detect surface flaws, micro-cracks, dimensional imperfections, and misalignments. Identifying all this with manual inspection is a tedious and time-consuming process, which doesn’t even guarantee accuracy. But with AI, accuracy is guaranteed.

Read More: Anomaly Detection Guide: Use Cases, Types, Methods, Benefits, and More

#2 Accelerated Quality Inspections

Another amazing advantage of AI-driven quality control is faster quality inspections. With faster and real-time quality inspections, supervisors can ensure the timely manufacturing of a product that also meets quality standards.

#3 Cost Reduction

One of the biggest benefits of AI-powered quality control in manufacturing is cost reduction with the detection of defects right when they occur or even before they occur. It reduces wastage, rework, and the efforts of operating the entire process, which are costly.

#4 Proactive and Predictive Quality Management

Unlike conventional quality control systems, AI-driven systems offer predictive insights to take proactive measures to reduce downtime and improve operational efficiency. For example, by analyzing wear and tear of manufacturing equipment or machinery, the system can raise an alert for its maintenance.

#5 Consistent Quality Standards

Artificial intelligence integration in quality control in the manufacturing industry can help companies ensure compliance with quality standards, which is crucial for a product’s overall success and customer satisfaction.

#6 Data-Driven Insights

AI-powered systems for manufacturing quality control make the most of data to derive insights associated with frequent quality improvements, issues, process inefficiencies, and opportunities. Using these insights, manufacturers can make data-based decisions.

Give it a read: Computer Vision Use Cases in Manufacturing: Explore Unique Applications for 2025

Which Technologies are Used for AI-Driven Quality Control

How has the integration of AI and machine learning transformed quality control in manufacturing? The simple answer to this question is- by utilizing these technologies along with computer vision, IIoT, deep learning, and edge computing, for quality control and monitoring in manufacturing. Explore more about these technologies below:

- Computer Vision: Computer vision captures product visuals from high-resolution cameras to feed input to AI-based manufacturing quality control systems and enable them to detect various types of defects, inaccuracies, and errors during product manufacturing.

- Machine Learning: ML algorithms process enormous amounts of production data to identify patterns and find anomalies to predict quality-related issues quickly and precisely.

- Deep Learning: The technology enables the AI-powered manufacturing quality control software to analyze different features of the product and compare them against defined standards.

- Industrial Internet of Things: IIoT-powered devices and sensors collect data such as temperature, vibration, and pressure of machines and equipment to identify deviations and raise an immediate alert for early intervention.

- Edge Computing: Edge computing speeds up the process of ensuring product quality by allowing AI quality control systems to process data at the source or origin. It ensures immediate defect detection and quick response, which further prevents downtime and production of defective products.

- Robotic Process Automation: AI in manufacturing quality control automates time-consuming and repetitive tasks. For instance, AI-powered systems utilize robotic process automation to perform accurate inspections with speed and accuracy.

- Predictive Analytics: Predictive analytics makes the most of historical and real-time production data for accurate forecasts about equipment, maintenance, and chances of breakdown.

You may like to read: Data Analytics in Manufacturing: Simplifying the Data with AI

How to Implement AI Quality Control in Manufacturing

Implementing artificial intelligence quality control in manufacturing is not an easy process. It requires hands-on experience in AI, ML, computer vision, and deep learning techniques, thorough knowledge of analyzing current infrastructure, and many other factors. If you have the same, follow these steps to implement intelligent automation for quality control in manufacturing processes:

Step 1: Decide the Goals and KPIs

The first step is to determine your goals, which starts with identifying the loopholes and quality control-related challenges. The goal could be to reduce delays in defect detection, minimize downtime, reduce rework, improve compliance, or enhance operational efficiency. Decide the KPIs to check the performance and accuracy of your AI-powered quality control system against defined standards.

Step 2: Collect and Prepare Data

Since AI-powered quality control systems utilize vast sets of data, the next step is to determine the reliable sources of data and define ways to collect that data. Once the data is collected, the next thing to do is to prepare the data for the AI model training. Clean and label data for accurate defect detection or any other desired purpose. Also, integrate technologies like computer vision with IoT sensors to ensure seamless collection of data from high-resolution cameras for real-time inspection of products.

Step 3: Training AI and ML Models

Train AI and ML models on the previously available defect data and production patterns. This will help the model to identify defects, predict equipment issues and maintenance time, and automatically adapt to new changes in the product designs and manufacturing patterns.

Step 4: Integrated the Trained Model with Existing Systems

In this step, integrate the trained AI and ML models in MES, ERP, or PLC systems to bring intelligence to quality control and monitoring for real-time defect detection, predictive quality control, and other use cases. The integration will ensure that the insights provided by these models are automatically applied to new workflows to facilitate informed decision-making.

Step 5: Testing

Test the model for accuracy, performance, and functionality. This would help to ensure that the model will deliver expected results and ensure high efficiency in manufacturing quality control operations.

Step 6: Continuous Optimization

Continuously optimize the AI model on new data to ensure it evolves along with the data and deliver more accurate results to bring efficiency in quality control.

One of the best practices for implementing AI in manufacturing quality control is to run pilot projects before scaling, i.e., apply AI-powered inspection on one production line initially. Once you find successful results, scale further. Another important consideration is to train your employees to make the most of AI-powered insights for quality control.

You may like to read: How AI is Proving as a Game-Changer in Manufacturing?

Partner with Quytech to Improve Quality Control in Manufacturing Using AI

Adopting artificial intelligence in manufacturing quality control requires great technical expertise; a lack of it may lead to the unsuccessful development of your AI-powered manufacturing quality control system. Therefore, partner with Quytech to build end-to-end AI-driven quality control and monitoring solutions from zero to one or integrate AI for defect detection, predictive analysis, compliance adherence, and other use cases.

We have highly experienced AI experts who thoroughly analyze your existing processes and challenges you encounter with quality control to build custom and scalable AI solutions backed by computer vision, machine learning, real-time analytics, and other technologies.

We are an experienced AI development company with more than 14 years of experience and over 200 dedicated AI experts to help you utilize AI for quality control to reduce costs, improve efficiency, and boost productivity. Apart from AI in manufacturing for quality control, we also hold in-depth expertise in AI-powered video analytics for manufacturing.

You may like to read: How to Implement AI in Your Business – Powering Possibilities

Conclusion

The manufacturing industry is undergoing a massive transformation with the implementation of artificial intelligence in quality control, warehouse and inventory management, supply chain management, and almost all other aspects. AI in manufacturing quality control automates inspection to bring accuracy, speed, efficiency, and boost productivity.

It offers real-time proactive insight into machine or equipment failure and maintenance to prevent downtime and ensure high product quality. By detecting defects in real-time, AI quality control reduces wastage and re-work and lowers production costs. With these amazing advantages and impactful outcomes, it is clear that the AI quality control in manufacturing is a must for building smarter and future-ready operations.

FAQs

AI can be used for quality control for detecting defects in real-time, analyzing production data, predicting equipment and machinery failures, and ensuring consistent product quality across all manufacturing operations.

These are four types of quality control in manufacturing that can be efficiently managed with AI integration:

– Process Control: Monitoring production processes for consistency.

– Acceptance Sampling – Checking a sample batch to evaluate quality.

– Control Charts – Tracking variations in production over time.

– Product Quality Control – Inspecting finished goods.

AI improves defect detection by using computer vision systems that scan every product on the assembly line. It identifies surface flaws, dimensional errors, and hidden anomalies with far greater accuracy and speed than manual inspections.

The cost of implementing AI in quality control varies depending on factors like the size of the manufacturing plant, level of automation required, type of AI solution (computer vision systems, predictive analytics, IoT integration), and customization needs.

When implementing AI quality control in manufacturing, you may encounter the following challenges:

– High implementation costs

– Difficulty with integrating with legacy systems

– Poor data availability and quality

– Lack of training

– Data privacy and security concerns

– Scalability challenges

– Regulatory and compliance hurdles

In the upcoming years, we may witness the following AI quality control trends:

– Hyper automation in quality control by implementing robotics and machine vision

– Shift from predicting defects to prescribing corrective actions in real time

– Creation of digital replicas of machines, products, and processes

– AI + IoT integration for smart factories

– Integration of generative AI in design and quality control

– Rise of edge AI to ensure real-time quality checks

– Sustainable and green manufacturing