It is quite common for the oil and gas industry to face unplanned equipment failures that impact or completely halt production. Apart from this, sudden fluctuations in oil prices, non-compliance with industry regulations, improving workers’ safety, and reducing the environmental impact of oil and gas production are some challenges the sector faces every day.

What if we tell you that one technology can overcome all these challenges? Here we are talking about predictive analytics in oil and gas. By implementing this technology, the companies can identify patterns that may hamper worker or workplace safety, equipment failure, production, or financial loss.

Predictive analytics offer critical insights based on which managers can make strategic decisions for the business’s benefit. Sounds amazing, doesn’t it?

Read this blog to know more about predictive analytics applications in oil and gas, benefits, real-world examples, challenges, and the implementation process.

Predictive Analytics in Oil and Gas: What Does It Mean

Predictive analytics in oil and gas means using the business data to predict the future. In a traditional setting, a company takes measures or changes its strategy after equipment breaks down, or when the price of oil or gas fluctuates.

This is entirely different after the implementation of predictive analytics. The technology uses equipment or machinery data (collected from sensors) to forecast whether there are chances of breakdown or malfunction.

Utilizing the other relevant data, predictive analytics can also make oil and pricing-related predictions. This enables the companies to take proactive measures or build the right strategy in advance to avoid downtime or financial losses.

Key Takeaways

- Predictive analytics in the oil and gas industry utilizes historical and real-time data collected by AI/ML models from machinery sensors to forecast issues before they occur.

- Predictive analytics applications oil and gas industry range from predicting equipment failure and optimizing production to ensuring predictive maintenance.

- AI/ML techniques that run in the background to make predictive analytics work are regression, time series analysis, and more.

- Benefits of using predictive analytics oil and gas are reduced downtime, cost savings, and improved workers’ and workplace safety.

- Shell, BP, and Chevron are three real-world examples of predictive analytics oil and gas.

- Deeper AI integration, digital twins, and real-time IoT-powered insights are the future trends we may witness in predictive analytics for the oil and gas sector.

How Does Predictive Analytics Work in the Oil and Gas Industry

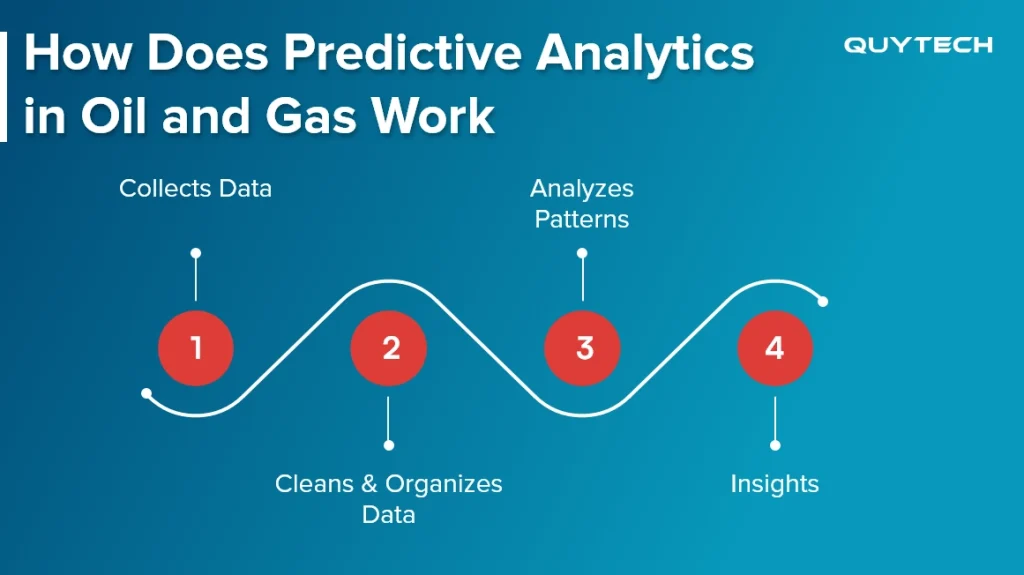

You know what predictive analytics does; now let’s understand how it does that. Well, predictive analytics follows a step-by-step process that starts with data collection and ends with providing crucial insights.

- Collects Data: It automatically connects with your production systems and sensors attached to equipment to collect data. The technology also looks into historical data.

- Cleans and Organizes Data: This step is highly crucial as the technology makes the data ready for analysis by removing errors or inconsistencies.

- Analyzes Patterns: By analyzing data patterns, predictive analytics algorithms find trends and signs of equipment failures or machinery wear and tear. It also gives information about a drop in production or changes in market demand.

- Insights: Based on the data analysis and pattern recognition, predictive analytics in oil and gas shows recommendations or steps that can prevent the occurrence of issues or minimize costs.

Understanding Predictive Analytics in the Oil and Gas Industry with an Example

There is a gas company that has installed over 200 machines that work all day long to produce gas. It is imperative for the company to keep a tab on the functioning of the machines to ensure their smooth functioning. Manually monitoring each of the machines would require at least a hundred professionals working in different shifts. Those professionals would be responsible for keeping a tab on sensors’ data and processing it in time to get an estimate of the breakdown.

Replace the same situation with predictive analytics, the company doesn’t need to put manual effort as the technology can auto-collect the data to determine various things, such as how hot the machines are or if they are vibrating more than usual. It can then raise an alarm for timely intervention.

On one side, it will prevent accidents in the facility, and on the other side, it empowers the organization to avoid machinery breakdown, which further impacts the production and supply of oil and gas.

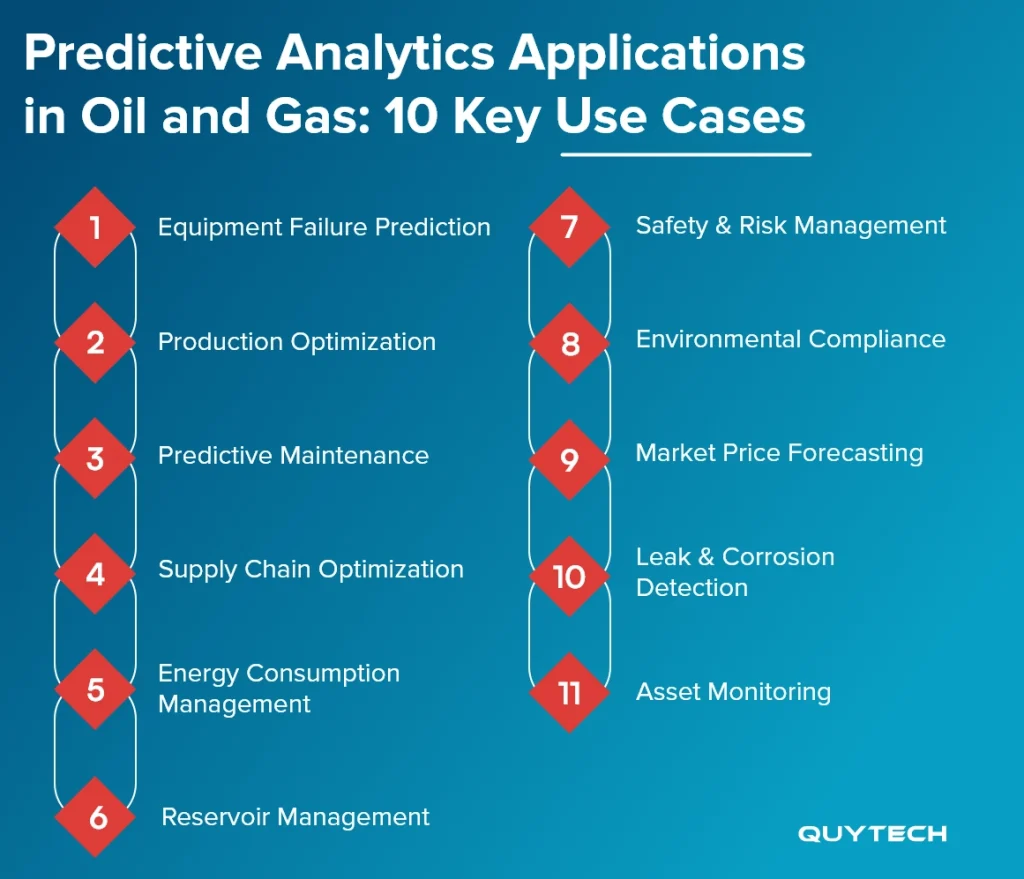

Predictive Analytics Applications in Oil and Gas: 10 Key Use Cases

Predictive analytics in oil and gas can be used to predict failure of equipment, optimize production, manage energy consumption, and in numerous other ways. Here are the detailed use cases that will help you understand the potential of this technology:

#1 Equipment Failure Prediction

The first application of AI predictive analytics oil and gas is that it can keep an eye on machines like pumps, compressors, and turbines. By collecting and processing data from the sensors attached to them, the technology detects early signs of wear or malfunctioning.

Here, the data that predictive analytics takes into account is temperature, vibration, and pressure. With these insights in hand, companies can adopt a proactive rather than a reactive approach and prevent costly breakdowns.

An example of using predictive analytics for equipment failure prediction is a refinery that uses the technology to detect unusual vibrations in a pump installed. Based on the insights, it can schedule maintenance and prevent the breakdown of that pump.

#2 Production Optimization

Another way oil and gas industry predictive analytics can be used is for optimizing the production of these two resources. The drilling and production operations data collected by predictive analytics tools or solutions makes it simple to identify where or which operation is in inefficient. It helps companies to work on that inefficiency and improve output.

The technology can even suggest what could be the best operational setting to implement in order to maximize production.

An example of production optimization powered by predictive analytics is an oil company where the machines auto-adjust drilling pressure, when needed, to increase extraction rates.

#3 Predictive Maintenance

Another amazing application of predictive analytics for oil and gas companies is that it helps companies with predictive maintenance. Now what is it? The technology recommends machine or equipment maintenance only when it is needed, not when it is scheduled. This minimizes downtime and maintenance costs.

An example to understand how predictive analytics help with predictive maintenance is a gas plant that replaces the machine’s valves only when the sensor shows signs of wear or tear. This can save labor costs as well as the cost of installing new valves.

#4 Supply Chain Optimization

Predictive analytics in supply chain optimization for the gas and oil sector can forecast demand and delays in transportation. It can even predict how much inventory would be needed. Having all these insights empowers companies to make sure their supply chain processes are smooth, transparent, and efficient,

An example of predictive analytics in supply chain optimization is a pipeline company that relies on this technology to forecast fluctuations in fuel demand. When the demand increases or decreases, AI predictive analytics automatically adjusts delivery schedules.

Delve Deeper: AI in Supply Chain Management: Navigating the Future of Logistics

#5 Energy Consumption Management

The next powerful use of predictive analytics is that it analyzes energy usage data to empower oil and gas companies to lower the amount of waste that is produced during the production of these two resources. It also improves the efficiency of the operations.

An example of using predictive analytics in energy consumption management is an offshore rig that automatically identifies which pump is consuming the most energy. This helps the company to optimize operations in a way to reduces the cost.

Deep Insights: AI in the Energy Sector: How AI Enhances Resource Management and Sustainability

#6 Reservoir Management

Dedicated predictive models or predictive analytics solutions can provide highly accurate details of oil and gas reserves. This can guide companies to make better drilling and extraction decisions.

An example of predictive analytics in reservoir management is a field that uses this technology to find which wells will produce the highest oil. With these insights, companies can put their effort into the most productive wells.

#7 Safety and Risk Management

Workers’ safety is another amazing predictive analytics application in the oil and gas industry. Predictive analytics tools can predict potential hazards by monitoring the data that comes from the sensors of machines and equipment.

Understand how predictive analytics ensure efficient safety and risk management in oil and gas with this example. Sensors detect dangerous or unusual gas levels on a rig. Predictive analytics tools process this data and automatically trigger an alarm to ensure immediate evacuation.

Also Read: AI Data Analytics for Supply Chain Risk Management

#8 Environmental Compliance

The next amazing use case of predictive analytics for the oil and gas industry is that it monitors emissions and discharges to make sure every operation that is being conducted or every process that is being performed complies with the environmental regulations.

An example of predictive analytics contributing to ensuring environmental compliance in an oil and gas business is a refinery that can predict high-emission periods. Based on the insights, it can adjust operations to not cross the defined legal limits.

#9 Market Price Forecasting

Predictive analytics models are capable of automatically collecting and analyzing historical as well as real-time market data. By thoroughly evaluating both, it can predict the fluctuations of the oil and gas prices.

An example of predictive analytics being used to predict the oil and gas market price is a crude oil trader that automates the adjustment of prices based on predicted fluctuations. They can maximize profit with this proactive approach.

Similar Read: How to use AI Predictive Analytics For Forecast Business Performance

#10 Leak and Corrosion Detection

Predictive analytics makes the most of sensor data and also considers previous equipment or machinery maintenance records to detect signs of leaks and corrosion. It can even detect pipeline degradation that can impact the quality of the production or may also lead to a workplace accident.

Here is an example to understand the predictive analytics role in leak and corrosion detection. An oil company that implements predictive maintenance into its pipeline monitoring system can detect corrosion and leaks before they turn into something major or lead to spills or environmental damage.

#11 Asset Monitoring

Real-time monitoring of critical assets is also one of the best use cases of predictive analytics oil and gas. These assets include pipelines, rigs, and refineries. With this monitoring, businesses in this industry can detect potential issues that may later impact the bottom line.

A perfect example of predictive analytics being used for asset monitoring in oil and gas industry is when the technology uses sensors to monitor a pipeline’s pressure and temperature. It can identify anomalies that may be a sign of a bigger risk.

You might be interested in: How the Predictive Analytics is Transforming Healthcare Industry

Core Model Types of Predictive Analytics in Oil and Gas

There are multiple models that run in the background to make predictive analytics work efficiently for the oil and gas operations. These models are:

#1 Regression Models

These models make the predictive analytics symptom capable of predicting numerical outcomes. This means companies can get insights associated with equipment wear, oil production rates, and energy consumption.

In simple terms, it would be able to predict the output each well will produce during a specific period or in a particular month.

#2 Classification Models

Classification models in predictive analytics are used to classify or categorize data into multiple groups. With this, businesses can make faster and more profitable decisions. For instance, this type of predictive analytics model can automatically identify which pump may not be working at its full capacity and which may stop operating.

#3 Time Series Models

Time series models can process the data collected from various sources. Based on this data, it can identify which trends are going to be there in the future. To understand, a time series model can predict fuel demand in the future. The refinery can optimize production capacity accordingly.

#4 Clustering Models

When similar data points need to be clustered together, the clustering model comes into action or can be used. By doing this, it helps companies to find hidden patterns or the segments of an operation.

#5 Neural Networks or Deep Learning Models

When oil and gas companies need advanced models to work on highly complex data, neural network or deep learning models can be used. These models work perfectly with large data sets and also vouch for providing highly accurate predictions.

Benefits You Get by Implementing Predictive Analytics in Oil and Gas Sector

The predictive analytics technology, when implemented correctly in oil and gas operations, reduces downtime, risk of accidents, and operational costs. It also enables decision makers to make data-driven decisions to ensure environmental compliance and improve efficiency. Let’s take a look at the benefits of predictive analytics in oil and gas in detail:

#1 Reduced Downtime

Predictive analytics predicts equipment or machinery failure beforehand; it means companies get the advantage of scheduling timely maintenance. It can help them avoid costly production halts or downtime.

#2 Saves Cost

Allowing companies to optimize maintenance schedules and minimize energy consumption by finding the sources that consume the most energy can reduce the overall operational cost significantly. It also optimizes production processes, which lowers the operational costs.

#3 Improved Workers and Workplace Safety

Continuous and real-time monitoring of machines and equipment can help quickly respond to the identified hazards that may lead to big accidents and compromise both workers and workplace safety.

Read More: Role of Artificial Intelligence (AI) in Monitoring Workplace Safety

#4 Enhanced Operational Efficiency

A business’s success is greatly dependent on how efficiently it runs its operations. By optimizing drilling, extraction, and production operations, predictive analytics helps an oil and gas company optimize efficiency and generate higher output without investing in additional resources.

#5 Better Decision-Making

Data-backed insights enable decision makers or managers in the oil and gas business to make informed decisions. Whether it is about deciding prices or investing in infrastructure and resources, data-driven insights greatly help.

Read More: How Predictive Analytics Powered by AI is Revolutionizing Decision-Making?

#6 Compliance with Regulations

Another benefit of predictive analytics in oil and gas industry is that it automatically verifies that all your processes and operations are complying with environmental regulations. This has also been explained in the use cases of predictive analytics in oil and gas section.

Predictive Analytics in the Oil and Gas Industry: Step-by-Step Implementation Process

Implementing predictive analytics in the oil and gas industry involves a series of steps to be followed. These steps are:

#1 Identify Challenges and Define Objectives

The first step is to define the goals you want to achieve with predictive analytics implementation. You may want to minimize equipment downtime or optimize production. Another goal could be to improve your workers’ safety or anticipate market trends or demands.

#2 Clean and Prepare Data

Define the relevant and reliable data sources, which could be sensors, machinery, production systems, and others. Once you collect data, clean it, and make it ready by organizing its structure for training AI and predictive analytics models. Make sure the data is consistent and error-free.

#3 Choose Analytics Techniques

The next step is to choose the right techniques and machine learning models that have been defined in this blog earlier. The selection of these techniques solely depends on the goals you want to achieve with predictive analytics implementation.

#4 Build and Train Models

Build a custom AI predictive analytics model or choose from existing ones. Train them on the data you have collected and made ready for training. Initially, you can begin by training the model on a specific dataset.

#5 Validate and Test

The next step is to validate and test the model. Check if it is delivering accurate output. Also, verify its performance before training the model on another dataset or deploying it within your existing infrastructure.

#6 Deploy and Monitor

Once you find it working as expected, implement predictive models into your operations. Keep a tab on its outputs and performance. Work on feedback received by the team using predictive analytics-powered tools or systems. Continuously train the model on new data.

Challenges You May Encounter While Implementing Predictive Analytics in the Oil and Gas Industry

While implementing predictive analytics oil and gas industry, you may face the following challenges, which can be overcome by partnering with the right and experienced technology partner:

- Poor data quality or data unavailability

- High cost of implementing predictive analytics in your current systems

- Difficulty in integrating predictive analytics within your existing legacy system can be a roadblock.

- You may face a challenge if you have a skilled workforce or if you don’t train your personnel to make the most of predictive analytics-powered systems.

- Cybersecurity risks are also one of the common problems one may face with oil and gas predictive analytics integration.

- Poor interpretation of data can also be a common problem that may lead to making wrong decisions.

Oil and Gas Companies Using Predictive Analytics: 3 Real-World Examples

Let’s take a look at some oil and gas companies that are using predictive analytics for multiple purposes:

#1 British Petroleum

The worldwide renowned company has implemented this technology for its drilling operations monitoring. Predictive analytics collects data from over 2 million sensors and monitors each drill operation in real-time to make sure worker and workplace safety. It also enhances operational efficiency.

#2 Chevron

Chevron is another big name that uses predictive analytics and AI-powered drones to monitor shale operations. The company currently uses the technology for Texas and Colorado locations to reduce maintenance downtime.

#3 Shell

It’s a big name in the oil and gas industry that needs no introduction. The company has implemented predictive and advanced data analytics to keep a tab on its oil and gas reservoirs. It also uses them for forecasting production.

The Future of Predictive Analytics in the Oil and Gas Industry

A report by Facts and Factors highlights that the predictive analytics market is expected to reach $60 billion by 2026. The market is expected to grow at a compound annual growth rate of 20%.

Considering this, it is clear that the future of predictive analytics in oil and gas is promising. In the future, we may witness the rise of AI and machine learning to drive smarter and safer operations. In the upcoming times, we may also see an increase in the use of real-time data from sensors, drones, and IoT devices.

The data can be used for various use cases, including equipment failure prediction, production optimization, and predicting demand associated with pricing, fuel, and others.

Another future trend associated with predictive analytics in oil and gas industry is the implementation of deep learning and digital twins technologies. Both these technologies can help try new experiments in real-world scenarios before making decisions.

How Quytech Helps

Quytech is a leading predictive analytics company with dedicated and certified AI and data engineers. Our team has worked with over 50 oil and gas companies across the globe. We have helped them to make the most of their complex operational data and get insights to improve operational efficiency, facilitate data-driven decision-making, and enhance workers and workplace safety.

Predictive analytics-powered solutions that we build for our clients also help them to comply with regulatory requirements and minimize the environmental impact of gas and oil production. We are trusted because of our commitment to customization and end-to-end solutions development expertise.

All our experts need is the goal you want to achieve with predictive analytics implementation. By thoroughly analyzing your goals and current business challenges, we build predictive analytics solutions that help you set benchmarks and stay competitive.

Conclusion

Predictive analytics has brought a wave of transformation in the oil and gas industry by empowering businesses to get data-backed insights. The data that used to be processed manually and required days or months to get insights can now be processed within minutes. All this is possible merely with predictive analytics implementation.

Basically, predictive analytics in oil and gas industry can process enormous amounts of data to predict and prevent equipment failure, optimize production, improve safety, and minimize environmental impact. The only thing that needs the utmost attention is finding the right partner who can help you implement it successfully.

FAQs

Yes, oil and gas predictive analytics can monitor emissions and detect leaks and corrosion that may risk the environment. It can even forecast potential environmental problems and ensure all processes are compliant with environmental regulations.

No, oil and gas companies of all sizes can benefit from predictive analytics. They can reduce costs, ensure worker safety, and optimize production.

Predictive analytics models work on data, which keeps evolving. Therefore, these models should also be updated and trained regularly to ensure precision in the output.

Yes. The technology can identify potential failure of equipment, highlight dangerous conditions like a gas leak, and monitor operations in real-time to prevent accidents and ensure workforce safety.

The cost of implementing predictive analytics in the oil and gas industry depends on the data complexity, AI models required, scale of operations, and a few other factors. Reach out to Quytech’s experts for an accurate estimate.