The manufacturing industry is moving towards automation. Now, manufacturers are leveraging cutting-edge technologies such as AI agents, the autonomous systems that can independently analyze data, make decisions, and take actions, to enhance production while eliminating errors, reducing operational costs, and keeping the quality in check, on the factory floor.

This growing reliance on AI agents is a major shift in how modern manufacturing operates. As a result, the market for AI agents, valued at $5.1 billion in 2024, is projected to reach approximately $47.1 billion by 2030, which signals intelligent, agile, and efficient manufacturing.

If you are also a manufacturer and interested in leveraging AI agents, then this blog is a must-read. In this blog, you will learn how AI agents are transforming manufacturing processes, their top use cases, and why embracing them now is essential for staying competitive.

What are AI Agents in Manufacturing

In manufacturing, AI agents are intelligent and autonomous systems that are integrated into the production areas to optimize the operations. They are different from traditional automation tools, as they can observe, learn, and act to achieve a specific goal.

These agents analyze data in real-time, make context-aware decisions, and even adapt to changes on the factory floor.

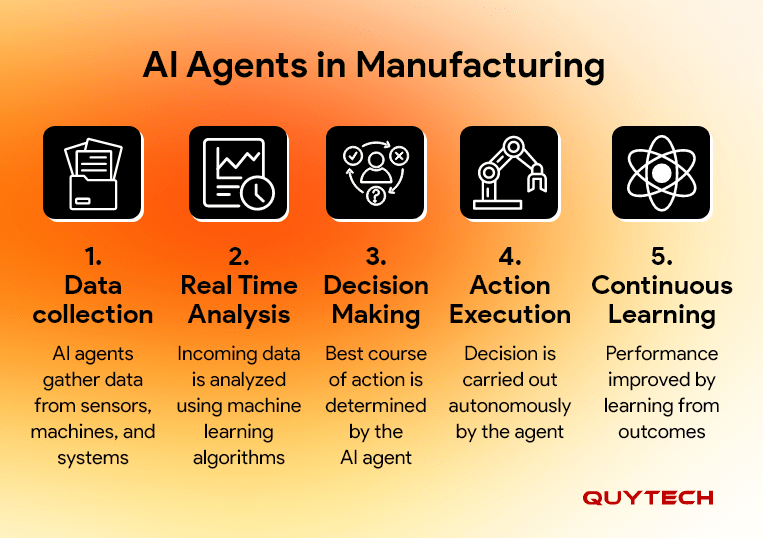

This is how AI agents work in manufacturing:

- Data Collection

First, AI agents gather data from sensors, machines, IoT devices, and ERP/MES systems continuously. This data usually includes temperature, vibration, machine speed, product quality, and more.

- Real-Time Analysis

While gathering data, AI agents analyze the incoming data using machine learning algorithms in real-time. They identify patterns, anomalies, and potential inefficiencies that may not be visible to human operators.

- Decision Making

Based on the analysis, the AI agent evaluates various options and decides on the optimal action. For instance, they may decide to slow down a machine to prevent overheating or reroute production to avoid congestion on the line.

- Action Execution

The AI agents then autonomously execute the decision, such as adjusting machine settings, sending alerts, updating inventory levels, or triggering maintenance protocols. This action is fully automated with no human intervention involved.

- Continuous Learning

Moreover, the AI agents improve their performance by learning from experience and results over time. They become more accurate in predictions and faster in responding to future issues.

AI agents have become integral team members in the modern manufacturing industry. Let’s explore the key benefits of adopting these agents across production lines.

You Might be Interested in: Types of AI Agents: Use Cases, Benefits, and Challenges

Benefits of Leveraging AI Agents in Manufacturing Industries

Let’s talk about the benefits of implementing AI agents in the manufacturing sector.

- Automates Repetitive and Complex Processes

The major advantage of AI agents in manufacturing is the automation. AI agents take over time-consuming and repetitive tasks, completing them independently without human intervention. This results in faster assembly lines and streamlined logistics.

In manufacturing, AI agents also manage complex systems like robotic welding or CNC (Computer Numerical Control) machining with high precision, while reducing manual oversight and increasing production speed, and maintaining consistency across every batch.

- Saves Time Across Operations

With the help of AI agents, manufacturers can speed up decision-making by processing vast amounts of real-time data from machines, sensors, and production systems.

Instead of waiting for analysis to be done by humans or manual coordination, the AI agents themselves analyze data and respond instantly. They make decisions like adjusting machine parameters, rerouting tasks, or notifying teams when anomalies occur.

This significantly reduces downtime, improves throughput, and allows production managers to make faster, smarter decisions without delays caused by traditional monitoring or approval processes.

- Reduces Operational Errors

Another benefit of implementing AI agents in manufacturing is reducing operational errors. In high-speed manufacturing environments, manual processes can cause errors, which may result in unnecessary delays and financial losses.

However, AI agents are leveraged to reduce this risk. They are used to automate calculations, detect patterns, and make informed decisions.

For example, AI agents can detect minor defects, raise concerns about missed assembly steps, and even wrong parts that are being used, all in real-time. These are some issues that even trained and experienced workers might overlook.

Overall, as the results, AI agents help in minimizing product recalls, scrap rates, and costly reworks, and lead to better output quality and reduced waste.

Read Also: How Enterprise AI Agents Are Redefining Business Processes

- Optimizes Resource Utilization

In manufacturing, AI agents ensure optimal usage of raw materials, energy, machinery, and labor. They constantly analyze production data, allocate tasks efficiently, predict demand for inputs, and reduce unnecessary energy consumption during off-peak hours.

For example, if any machine in the factory is underperforming, the AI agent can divert the work to a more efficient unit to ensure that there will be no resources wasted. This leads to leaner operations with maximum output and minimal overhead costs.

- Enhances Production Planning and Forecasting

AI agents in manufacturing benefit manufacturers by enhancing production planning and forecasting. They analyze the historical data in real-time and forecast demand trends, production obstructions, and inventory needs with high accuracy.

Manufacturers can then align production schedules, supply orders, and staff accordingly and avoid overproduction or underutilization.

This proactive planning helps maintain a consistent supply chain and reduces last-minute disruptions, giving manufacturers a strong edge in meeting delivery timelines and customer expectations.

- Improves Workplace Safety

Last but not least, AI agents play a vital role in improving safety and reducing accidents in the manufacturing industry. AI agents are deployed to keep an eye on whether safety protocols are being followed by the workers or not. If not, the agents will raise the issue in real-time, alerting the supervisors.

Moreover, AI agents constantly monitor machine conditions, temperature levels, emissions, and operator behavior to detect risks before they become hazards.

They can, for instance, shut down a machine if it starts to overheat or alert a technician about abnormal vibrations. This way, AI agents not only protect human workers from accidents but also prevent damage to expensive equipment.

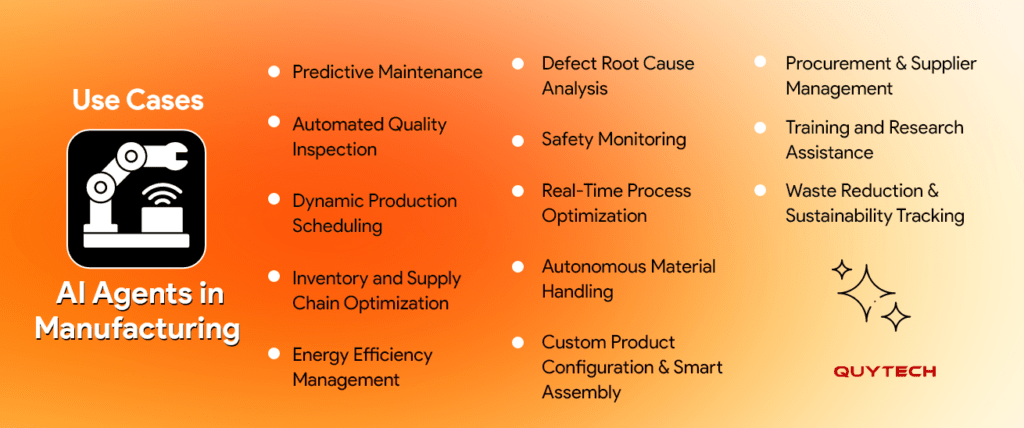

Top Use Cases of AI Agents in Manufacturing

The following are the best applications of AI agents in the manufacturing sector.

- Predictive Maintenance

Predictive maintenance is one of the top use cases of AI agents in manufacturing. The AI agents are deployed in manufacturing units to monitor machinery using real-time data from Internet of Things (IoT) sensors.

These autonomous agents analyze various factors, such as temperature, vibration, and motor speed, to predict when equipment is likely to fail.

Moreover, instead of scheduling routine maintenance, AI agents detect anomalies and recommend maintenance only when it is necessary.

- Automated Quality Inspection

Another application of AI agents in manufacturing is automating quality inspection of goods being manufactured. AI agents are combined with computer vision technology to inspect products on the assembly line in real time.

They detect surface defects, dimensional inaccuracies, misalignments, and other quality issues far faster and more accurately than manual inspections.

Manufacturers from sectors like electronics, pharmaceuticals, and packaging are increasingly relying on these AI agents for consistent, high-precision quality inspection and control.

- Dynamic Production Scheduling

Among the top use cases of AI agents in manufacturing is production scheduling, which AI agents analyze production variables, such as machine availability, worker shifts, inventory levels, and incoming orders, to create and adjust schedules in real time.

Also, when a delay occurs, the AI agents in manufacturing automatically reschedule tasks to keep production flowing efficiently.

- Inventory and Supply Chain Optimization

AI agents are implemented in manufacturing to manage and optimize inventories effectively. They track raw material usage, delivery timelines, and stock levels, and even forecast material needs based on historical trends and current production, and place automatic restock orders when levels drop.

Moreover, if in any case, there is a disruption in the supply chain, the AI agents suggest alternative vendors or shift production schedules, ensuring the continuity and on-time production.

- Energy Efficiency Management

Manufacturers also use AI agents to monitor and manage energy consumption for equipment, lighting, and HVAC (heating, ventilation, and air conditioning) systems.

The AI agents leverage machine learning capabilities to identify the inefficiencies in the system and reduce power usage automatically during the non-peak hours or idle states.

Additionally, AI agents also recommend energy-saving measures that help manufacturers significantly reduce energy costs and support sustainability.

- Defect Root Cause Analysis

In manufacturing, AI agents are leveraged to analyze and trace the root cause of defects occurring across the production lines. These agents find whether it is because of faulty raw materials, machine issues, or some operator error.

AI agents identify patterns by examining historical data and suggest corrective actions to prevent recurring issues in high-precision industries where consistent quality cannot be compromised.

- Safety Monitoring

Safety monitoring is one of the top use cases of AI agents in manufacturing. They help ensure the safety of manufacturing lines by monitoring environmental conditions continuously.

Also, AI agents in manufacturing detect unsafe behaviors or conditions and alert workers or shut down machinery in real time.

Moreover, some AI agents also use computer vision to track compliance with safety gear and protocols, which play a crucial role in reducing accidents and enhancing worker well-being.

- Real-Time Process Optimization

AI agents are leveraged in manufacturing to optimize processes in real-time by analyzing production data and detecting inefficiencies and optimizing parameters such as speed, temperature, pressure, or feed rate.

AI agents continuously monitor, learn, and adjust variables, and ensure that the manufacturing process stays within optimal performance ranges.

- Autonomous Material Handling

The other use case of AI agents in manufacturing is to power autonomous systems such as robotic arms, conveyor belts, and AGVs (Automated Guided Vehicles) to manage material movement across the factory floor.

The AI agents determine the best paths, avoid collisions, and prioritize urgent tasks to ensure the timely supply of components to assembly lines and seamless logistics within the production facility.

- Custom Product Configuration and Smart Assembly

For manufacturers, AI agents also help with mass customization by managing dynamic product configurations based on customer requirements.

AI agents control smart assembly lines that adjust in real time, for example, retooling machines, updating instructions, and sequencing tasks for custom builds, without disrupting standard production, ensuring both flexibility and speed.

- Procurement and Supplier Management

In the manufacturing sector, AI agents streamline the procurement process by analyzing supplier performance, lead times, and pricing trends.

They automatically select the best suppliers, forecast raw material needs, and generate purchase orders.

Moreover, in case of delays or supply chain disruptions, they automatically identify alternatives and adjust procurement schedules, ensuring supply continuity, cost-efficiency, and stronger vendor relationships.

- Training and Research Assistance

In Industry 4.0, AI agents support workforce training by delivering interactive tutorials, real-time feedback, and augmented and virtual reality-based learning modules tailored to specific machinery or processes.

AI agents are used by manufacturers to analyze trainee performance and suggest personalized learning paths. Similarly, in R&D labs, they are implemented to assist engineers by analyzing test results, simulating process changes, and identifying improvement areas.

- Waste Reduction and Sustainability Tracking

The last entry on the list of top applications of AI agents in manufacturing is waste reduction and sustainability tracking. AI agents help manufacturers monitor material waste and energy consumption, and identify opportunities to reuse scrap, optimize packaging, or reduce excess input usage.

Moreover, they also track sustainability KPIs like emissions, water usage, and resource efficiency. These insights allow factories to align with environmental regulations and green manufacturing practices.

Top Manufacturers Already Using AI Agents

In this section, read about how AI agents are being used in manufacturing units and factories of leading brands and manufacturers.

- Siemens

Siemens, a multinational technology conglomerate, has deployed its Industrial Copilot at its electronics facility in Erlangen.

This AI agent works with soldering machines and interprets complex machine error codes and instantly recommending actions to operators and maintenance staff.

- Otto Group

An international e-commerce and service group, the Otto Group, is transforming its distribution centers through embodied AI agents. They’ve implemented pick-and-place robots that autonomously recognize and manipulate unfamiliar objects.

Moreover, these AI agents can also be guided using natural language processing, dramatically simplifying warehouse automation and pushing the limits of what tasks robots can learn and perform.

- BMW and Mercedes-Benz

Among the top automobile manufacturers, BMW and Mercedes-Benz are pioneering the use of humanoid robotics powered by AI agents.

BMW has started piloting Figure’s humanoid robots at its Spartanburg plant to assist with complex and dynamic assembly tasks.

Meanwhile, Mercedes is exploring similar capabilities of AI agents to enable next-gen flexibility in automotive production.

- Rolls-Royce

Rolls-Royce, a major manufacturer of aero engines and luxury cars, is leveraging AI agents for its internal day-to-day operations and processes.

The company has implemented AI agents to reduce manual workloads, optimize service workflows, and enable faster, data-driven decisions.

How Quytech Can Help Manufacturers Develop and Implement AI Agents

At Quytech, we provide you with end-to-end AI agent development services to build custom AI agents for your manufacturing units, factories, and more.

We specialize in building AI agents leveraging agentic AI, AI, natural language processing (NLP), computer vision, machine learning, and other leading technologies, so that the agents will help you achieve your desired goals.

We help you develop your AI agents for manufacturing with:

- Expert Consulting and Strategy

Our experts will assess your business needs and identify high-impact areas where AI agents can reduce costs, boost productivity, and automate complex tasks.

- Custom AI Agent Development

Our team of experienced developers will design and develop AI agents tailored to your factory operations and ensure seamless integration with existing systems and maximum ROI.

- Data Infrastructure & Integration

We help you collect, clean, and structure factory data, enabling AI agents to make real-time, intelligent decisions based on accurate machine and process insights.

- Compliance & Security

AI agents developed by our team perfectly align with industrial compliance standards and ensure data privacy and cybersecurity across your manufacturing environment.

- Ongoing Support & Optimization

Beyond deployment, we monitor and continuously improve the performance of deployed AI agents to make them adapt to new goals, changing workloads, and evolving production lines.

Conclusion

Manufacturers are no longer preparing for AI agents, but actually they have deployed them in the deploying them in factories of Siemens, BMW, Rolls-Royce, and others.

AI agents are being leveraged in manufacturing for their wide range of applications, such as predictive maintenance, inventory and supply chain management, safety monitoring, custom product configuration, training and research, and more.

By developing custom AI agents, you can also join the list of top manufacturers using smart solutions and reap benefits such as automating repetitive tasks, saving time, reducing operational costs, and more.

So, without waiting any more, reach out to Quytech and get your tailored AI agents development started.

Frequently Asked Questions

AI agents in manufacturing are autonomous systems that are implemented to analyze data, make decisions, and execute tasks, such as monitoring machines, optimizing production, or managing inventory, all without any participation from humans.

AI agents can help you automate repetitive processes in your manufacturing units. Along with this, they also reduce downtime, improve quality control, cut operational costs, and boost the overall efficiency of your manufacturing units.

Various emerging technologies are used in AI agents like machine learning, computer vision, natural language processing, IoT, edge computing, and more. These technologies help AI agents with sensing, understanding, and acting intelligently in dynamic manufacturing environments.

The development time may range from 4 months to up to a year, depending on how complex the AI agent is, data availability, its specific use case, development team, and more.

Q1. What are AI agents in manufacturing?

AI agents in manufacturing are autonomous systems that are implemented to analyze data, make decisions, and execute tasks, such as monitoring machines, optimizing production, or managing inventory, all without any participation from humans.

Q2. Why should I implement AI agents in my manufacturing units?

AI agents can help you automate repetitive processes in your manufacturing units. Along with this, they also reduce downtime, improve quality control, cut operational costs, and boost the overall efficiency of your manufacturing units.

Q3. Which emerging technologies are used in AI agents?

Various emerging technologies are used in AI agents like machine learning, computer vision, natural language processing, IoT, edge computing, and more. These technologies help AI agents with sensing, understanding, and acting intelligently in dynamic manufacturing environments.

Q4. How long will it take to develop a custom AI agent for manufacturing?

The development time may range from 4 months to up to a year, depending on how complex the AI agent is, data availability, its specific use case, development team, and more.

Q5. How can I develop an AI agent for my factory?

To develop AI agents for your factory, you can partner with Quytech, the leading AI agent development company. Contact our team today to get started.